Machines: Our Precision Technology

We’d like to introduce our quality, precision technology, and industry-leading equipment.

Software to Parts: How We Get There.

Here at Peterson Machining we use a variety of softwares to bring Solid Models to parts in hand. At this virtual start is the Part Solid Model, models for fixtures and tooling used in machining to inspection. To do this, we are using the latest versions of Mastercam, Vericut, Speroni Edge Pro, CMM Manager, and Focus Scan from Nikon Metrology. Mastercam is used to program all our Multi Axes CNC machines. This is where the part, machine, fixtures and tooling models all come together and the processes for machining are formulated into programs for the CNC machines. The tool assemblies used come from our Speroni Futura STP 66 tool presetter and Edge Pro software. In this virtual world all aspects of the parts machining are verified. The final verification of the actual code that the CNC will use to make the part is done in Vericut. This full rendering of the machine making the part to the exact code posted by Mastercam through our proprietary posts adds a great certainty. Now having fully made the part in virtual it goes to the machine that is best suited to make it. Once the part is completed and now in hand it moves to inspection. Here in inspection the original Part Solid Model is used to verify the physical part to. Using one of our two DCC 5 axis CMMs with CMM Manager and/or Focus Scan from Nikon Metrology we write an inspection program. Closing the loop from solid model to a machined part that matches all the parts specifications we have used some very sophisticated software and machine tools.

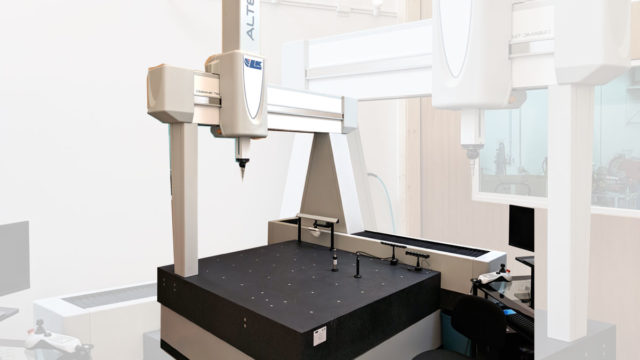

Inspection Equipment

Quality and Automation Validating AS9100D Certification

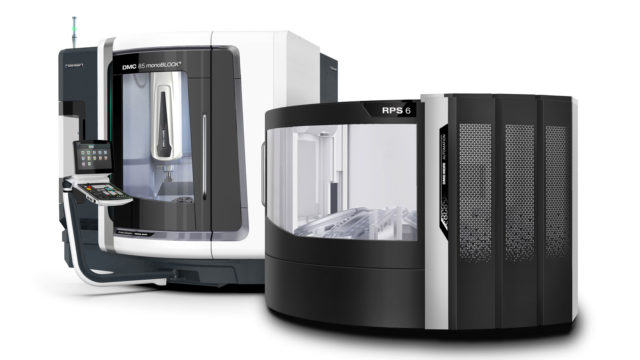

5-axis

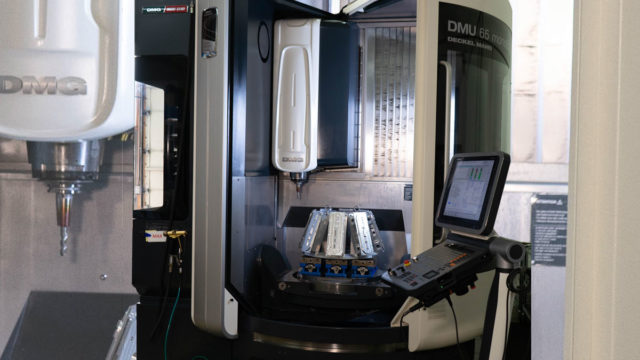

4-axis

Vertical Machining

We take care to make sure even the last steps of detail are seen to.

~Todd Peterson

Our Kaeser compressors, are German built machines and are foundational to the functioning of our shop. All machines must have a reliable supply of “instrument quality” air.

This means air that has no oils or water. This quality air is imperative for the air supply to our CMM (Coordinate Measuring Machines) as well as the Multi Axis CNC machines.

This same air is used to dry parts in the washing process.