We would not be the shop that we are today without DMG MORI’s DMU 65 monoBLOCK®.

Peterson Machining Inc. founded in 1989, is a Woman Owned Company based in Boulder, Colorado. Peterson’s founders have long been believers in quality and forward thinking. It is that thought process that was a key factor in the decision to partner with DMG MORI on multiple machine purchases.

DMG MORI has superior technology. We looked at other suppliers, but they didn’t come close to measuring up.

Ronda Peterson, CEO adds, “we wanted longevity, something that we know will be competitive for five, ten, fifteen years. We take meticulous care of our machines and care about every part of our company, our customers and our processes.”

Ronda Peterson, CEO adds, “we wanted longevity, something that we know will be competitive for five, ten, fifteen years. We take meticulous care of our machines and care about every part of our company, our customers and our processes.”

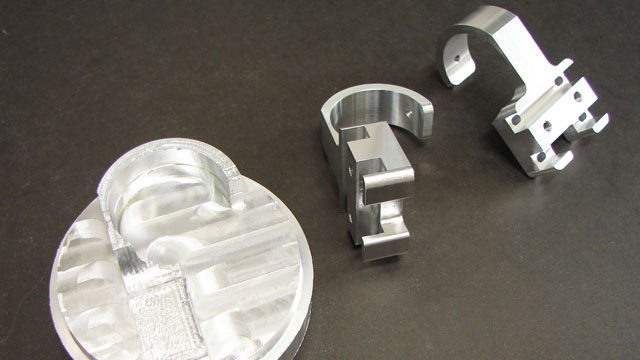

A go-to partner for leading companies in Aerospace, Automotive, Technology and beyond…

There have been ups and downs throughout their journey from a very small job shop that was barely known, to being a “go-to partner” for leading companies in Aerospace, Automotive, Technology and beyond. Peterson Machining felt at a disadvantage without the industry leading DMG MORI 5-axis technology, so after a very short time they decided to take advantage of the only partnership they deemed necessary.

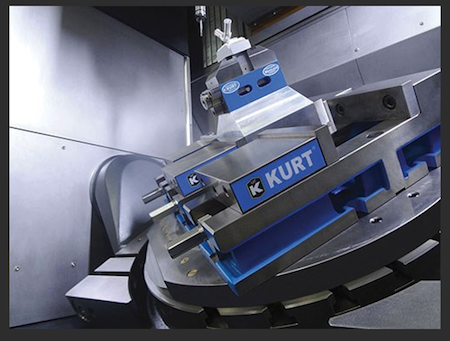

After watching a demonstration of the DMU 65 monoBLOCK®’s capabilities at DMG MORI’s Innovation Days, the Petersons were so impressed by the machine’s superior technology that they purchased one that same week. Now with two DMU 65 monoBLOCK®’s, Peterson Machining has grown its team and customer base to new heights.

We’re a job shop and never know what’s coming in the door,” says Todd Peterson. “With its small footprint and large work envelope, the flexible DMU 65 monoBLOCK® makes sense for a shop of our size.

“The DMU 65 monoBLOCK® opened the door for vast amounts of new business,” states Ronda Peterson. “Customers have found us through a web search associated with capabilities, while others came to us once it became known that we could do what others could not. We even have business from LASP / NASA and have become a key partner in the production and development for RETÜL.”